We have unrivalled experience providing services to the semiconductor industry.

Advanced Furnace Technology have over forty years’ experience manufacturing bespoke high temperature process furnaces for the Material Sciences sector.

Having designed and installed some of the first MOCVD machines in the world, we have exceptional knowledge and experience when it comes to understanding the problems faced by today’s epitaxial engineers.

Quality, Reliability and Confidentiality

Our business success is down to providing customers with the industry insight, product quality, service reliability and the total confidentiality they expect. This gives our clients the confidence in their furnace parts performing to a consistently high standard, freeing them to concentrate on running their process at maximum efficiency.

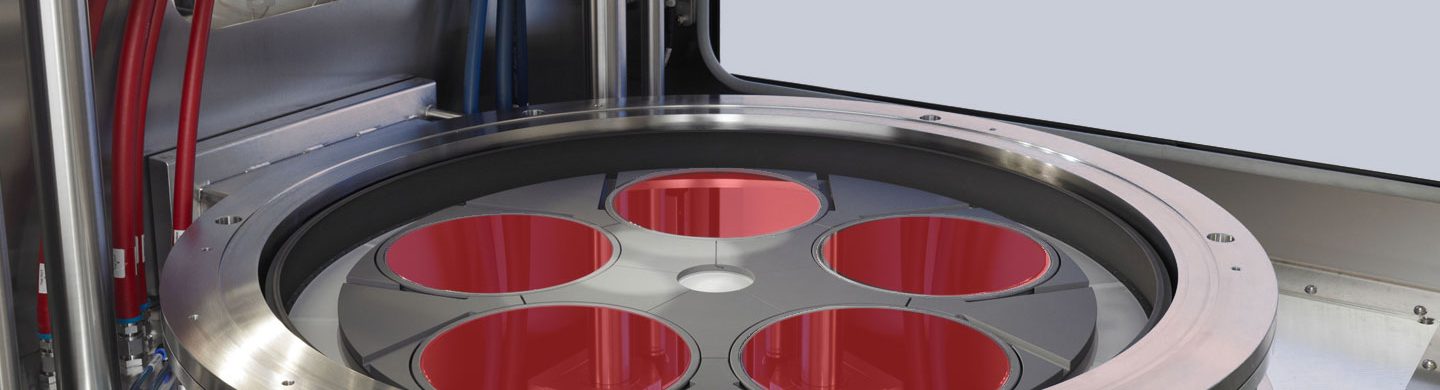

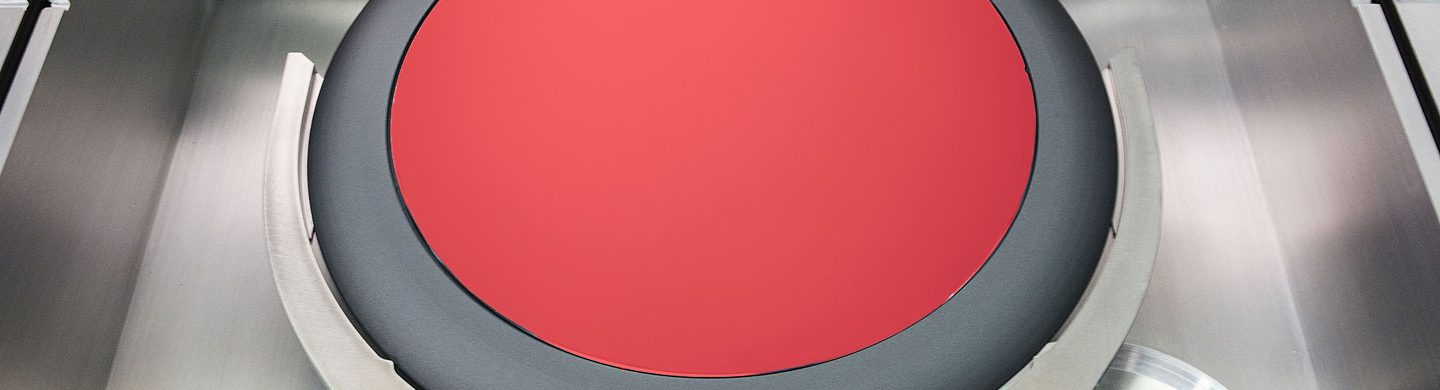

AFTech provides three primary areas of service; Graphite Cleaning, Graphite Purification and Graphite Coating.

Our core business is within the III-V’s MOCVD sector, however, we also regularly work with the Nuclear, Electronic, Energy, Defence and Aerospace industries.

If you have any questions regarding our service, please don’t hesitate to get in touch on +44 (0) 1223 461321 or email us today. Alternatively we have an online enquiry form here.