A specialist high-temperature graphite purification and out-gasing service.

Advanced Furnace Technology offers a unique high-temperature vacuum purification process to remove the metals and gases left behind from the graphite manufacturing process.

By removing residual trace metals and dopants, your graphite parts will last longer, be more reliable, and perform more consistently.

Are you seeking improved emissivity, temperature uniformity or more heating efficiency from your graphite? Reducing impurities down to parts per million (ppm) will help you achieve this goal.

Exceptional purity and consistent performance

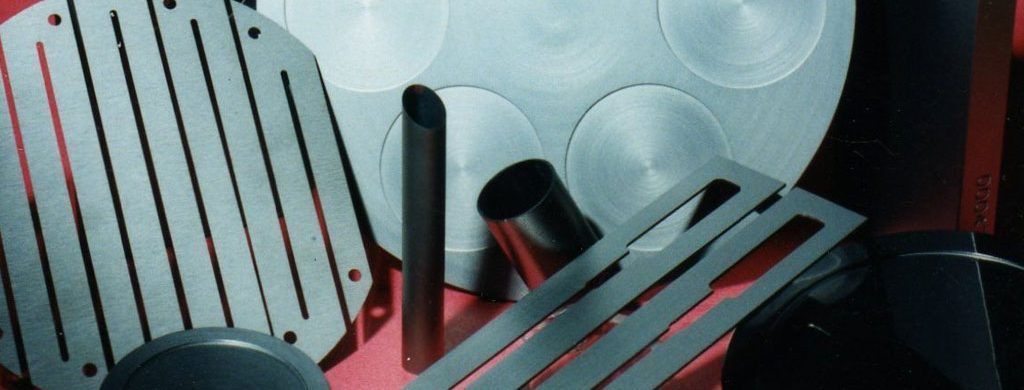

Using our proprietary high-temperature, low-pressure process we remove contaminants from solid graphite parts for the MOCVD, Nuclear and Space industries.

We extract metals such as copper, iron and aluminium and remove the residual sulphur from both new and used graphite parts, purifying solid graphite in any configuration up to 1,000mm long.

If your graphite is coated with impurities, our graphite cleaning service will restore used parts to a nearly new condition, then our purification process will remove all remaining trace elements and volatile gases.

Extend the lifetime of your products and improve your yield by ensuring your process graphite is exceptionally pure.

If you want to permanently reduce the permeability of your graphite, we also offer a high purity pyrolytic graphite coating service.

Once purified, all parts are sealed under vacuum in foil bags with a nitrogen outer to minimise contact with atmospheric gases and ensure they reach you in an ultra-pure state.